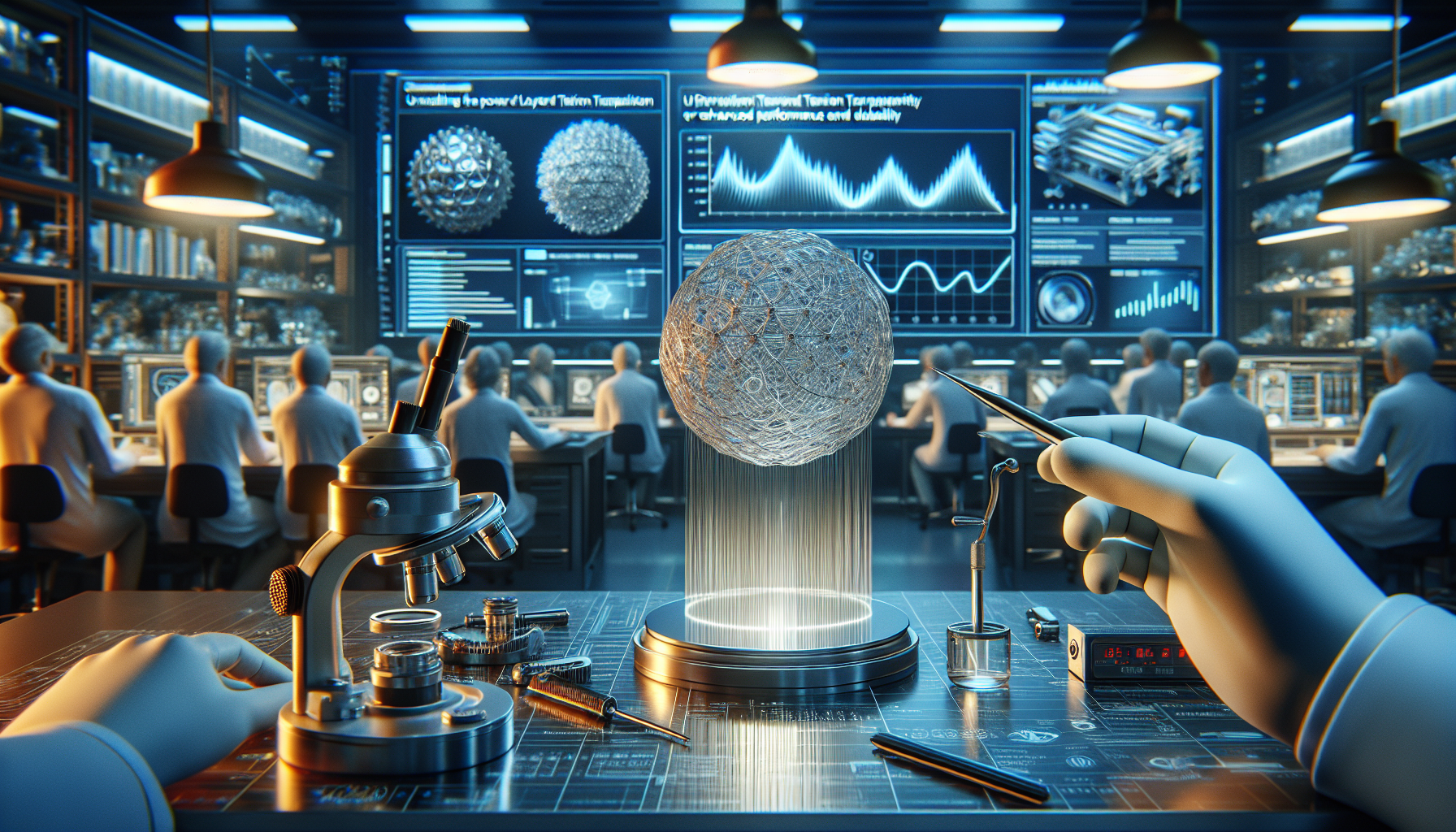

In the ever-evolving world of material science, breakthroughs are the cornerstones that propel technology and innovation to new heights. As industries relentlessly pursue materials that offer not only enhanced performance but also remarkable durability, the spotlight increasingly falls on pioneering advancements that promise to reshape our understanding of what’s possible. Among these groundbreaking developments, the concept of strain layer transparency emerges as a transformative force, holding the potential to redefine material capabilities and applications. 🌟

At its core, strain layer transparency is an innovative approach that intricately manipulates the structural composition of materials to unlock new levels of performance. By meticulously layering materials with different strain profiles, scientists and engineers can create composites that exhibit unprecedented strength, flexibility, and resilience. This technique, rooted in the fundamental principles of physics and materials science, offers a window into a future where materials are not just passive components but active contributors to the efficiency and longevity of products and systems. Imagine a world where airplanes are lighter yet sturdier, electronics are more robust yet delicate, and infrastructure is both resilient and adaptable. This is the promise that strain layer transparency holds.

The journey into the realm of strain layer transparency is not just a tale of scientific discovery but also one of practical application. As we delve deeper into this topic, we will explore how this breakthrough is being harnessed across various sectors. From aerospace to electronics, and from automotive to construction, the impact of strain layer transparency is already being felt, paving the way for innovations that were once confined to the realm of science fiction. Moreover, this exploration will shed light on the collaborative efforts between researchers, engineers, and industry leaders who are working tirelessly to bring these advancements from the laboratory to real-world applications. Their stories of perseverance and creativity underscore the transformative power of strain layer transparency.

As we navigate through this comprehensive exploration, you can expect to gain insights into the science behind strain layer transparency, the challenges that have been overcome, and the exciting future that lies ahead. We will dissect the mechanics of how these layered structures work, examine case studies of successful implementations, and discuss the potential pitfalls and ethical considerations that accompany such powerful innovations. This journey promises not only to inform but also to inspire, offering a glimpse into a future where the boundaries of material performance and durability are continually expanded. So, buckle up as we embark on this exciting adventure into the world of strain layer transparency—a journey that promises to reshape industries and redefine possibilities. 🛠️

Understanding Strain Layer Transparency: An Overview

Strain layer transparency is a groundbreaking concept in the realm of material science that has caught the attention of researchers and industry professionals alike. At its core, this concept involves the strategic manipulation of material layers to optimize transparency and strength, leading to enhanced performance and durability. This breakthrough innovation has vast applications across various sectors, including electronics, aerospace, and automotive industries. By understanding the principles and mechanisms behind strain layer transparency, stakeholders can harness its potential to develop superior products that meet the ever-growing demands of modern technology.

The concept of strain layer transparency revolves around the idea of engineering material layers in such a way that they maintain or improve their transparency without compromising their mechanical integrity. This involves precise control over the thickness, composition, and arrangement of layers to achieve the desired optical and structural properties. Researchers employ advanced techniques such as molecular beam epitaxy and chemical vapor deposition to create these layered structures with remarkable precision. By tailoring the stress and strain within these layers, it is possible to achieve materials that not only exhibit enhanced transparency but also demonstrate increased strength and durability.

One of the key advantages of strain layer transparency is its ability to address the challenges posed by traditional materials in various applications. For instance, in the field of electronics, transparent materials are crucial for the development of high-performance displays and touchscreens. Traditional transparent materials like indium tin oxide (ITO) often suffer from brittleness and limited flexibility. By implementing strain layer transparency, manufacturers can produce materials that are not only highly transparent but also flexible and robust, paving the way for innovative designs and enhanced user experiences.

The Science Behind Strain Layer Transparency

At the heart of strain layer transparency lies the intricate interplay between material properties at the atomic level. This involves a delicate balance between lattice mismatches, stress, and strain within the layered structures. When materials with different lattice parameters are grown together, the resulting strain can either enhance or hinder transparency, depending on how it is managed. By carefully controlling the strain, researchers can manipulate the optical and mechanical properties of the material to achieve the desired level of transparency and strength.

The process of creating strain layer transparency begins with the selection of appropriate material systems. Materials with similar lattice constants are often preferred to minimize the mismatch and reduce the overall strain. However, by introducing controlled amounts of strain, it is possible to tune the bandgap and refractive index of the material, thereby enhancing its transparency. This requires a deep understanding of crystallography and material science, as well as access to state-of-the-art fabrication techniques.

| Heterostructure System | Advantages | Disadvantages |

|---|---|---|

| InGaAs/InP | High electron mobility, excellent thermal stability | Complex fabrication process, cost |

| AlGaAs/GaAs | Good optical properties, well-established technology | Lattice mismatch issues, limited wavelength range |

| SiGe/Si | Compatible with existing silicon technology, tunable bandgap | Strain-induced defects, limited transparency |

Applications and Implications of Strain Layer Transparency

The implications of strain layer transparency extend far beyond the realm of academic research. In the electronics industry, this technology holds the promise of revolutionizing display technologies. For instance, the development of flexible, transparent displays could transform the way we interact with devices, enabling new form factors and applications. Similarly, in the realm of photovoltaics, strain layer transparency can lead to the creation of more efficient and aesthetically pleasing solar panels, paving the way for greater adoption of renewable energy sources.

Moreover, the aerospace and automotive industries stand to benefit significantly from strain layer transparency. Lightweight and transparent materials are in high demand for various applications, such as windows, windscreens, and sensor covers. By leveraging strain layer transparency, manufacturers can produce materials that not only meet the stringent safety and performance requirements of these industries but also offer improved durability and longevity.

For a more visual understanding of how strain layer transparency impacts material performance, check out this informative video from the Science Channel. Watching this video will give you insights into real-world applications and further illustrate the transformative potential of this technology.

Challenges and Future Directions

While the potential of strain layer transparency is immense, several challenges need to be addressed to fully realize its benefits. One of the primary hurdles is the complexity of the fabrication processes involved. Developing the necessary infrastructure and expertise to produce these advanced materials on a commercial scale requires significant investment and collaboration across disciplines. Additionally, maintaining the stability and performance of these materials under varying environmental conditions remains a critical area of research.

Looking ahead, the future of strain layer transparency appears promising, with ongoing advancements in material science and fabrication techniques. Researchers are continually exploring new material combinations and methods to optimize strain management and improve the scalability of these technologies. As the understanding of strain layer transparency deepens, it is likely that new and unforeseen applications will emerge, further expanding the impact of this innovation across multiple industries.

- Explore the potential of strain layer transparency in flexible electronics.

- Investigate the role of strain layer transparency in enhancing photovoltaic efficiency.

- Consider the environmental impact of implementing strain layer transparency in industrial applications.

Conclusion

Conclusion: Unveiling the Power of Strain Layer Transparency

The exploration of strain layer transparency in materials science marks a significant milestone in the realm of innovation, paving the way for advancements that promise enhanced performance and durability across various applications. Throughout this article, we have navigated the intricate landscape of this breakthrough, delving into its principles, applications, and implications for the future of material innovation.

At the core of strain layer transparency is the ability to manipulate and optimize the mechanical and optical properties of materials. By understanding the stress distribution and strain effects within layered structures, scientists and engineers can design materials that exhibit unprecedented levels of resilience and performance. This capability is particularly critical in industries such as aerospace, electronics, and construction, where materials are constantly pushed to their limits.

One of the key points discussed is the fundamental principle of strain layer transparency, which involves the strategic layering of materials to create a composite structure that efficiently manages stress and strain. This not only improves the material’s strength and flexibility but also enhances its transparency, making it ideal for applications where optical clarity is essential. The interplay between these properties opens up new possibilities for innovations in smart windows, flexible displays, and even advanced photovoltaic systems.

Moreover, the potential applications of this technology are vast and varied. In the field of aerospace, for instance, the development of lighter and more durable materials can significantly enhance the performance and fuel efficiency of aircraft. Similarly, in the realm of consumer electronics, the creation of flexible and transparent materials can lead to the development of next-generation devices that are both robust and aesthetically pleasing.

The implications of strain layer transparency extend beyond immediate technological advancements, hinting at a future where sustainable and efficient materials play a central role in our lives. By optimizing material performance and durability, we can reduce waste, conserve resources, and promote sustainable practices across industries. This aligns with the global push towards environmentally conscious innovation, underscoring the importance of continued research and development in this field.

As we conclude our exploration of strain layer transparency, it is crucial to acknowledge the collaborative efforts of scientists, engineers, and industry leaders who are driving this innovation forward. Their contributions are instrumental in transforming theoretical concepts into practical applications, ultimately reshaping the landscape of material science.

The importance of strain layer transparency cannot be overstated, as it represents a convergence of scientific insight and practical ingenuity. It challenges us to think differently about materials, pushing the boundaries of what is possible and inspiring a new generation of innovations. This is a call to action for researchers, developers, and industry professionals to embrace this breakthrough and explore its potential applications in their respective fields.

We encourage readers to engage with this topic further, whether through sharing insights, collaborating on research initiatives, or implementing these concepts in practical settings. By fostering a community of innovation and exploration, we can collectively harness the power of strain layer transparency to drive progress and create a more sustainable and technologically advanced future.

In closing, the journey of unveiling the power of strain layer transparency is one of discovery, innovation, and inspiration. It invites us to imagine a world where materials are not just passive components, but active enablers of change and progress. As we stand on the brink of this new era in material innovation, let us seize the opportunity to redefine the limits of what materials can achieve and how they can transform our world for the better.

🌟 For further reading on the subject, we recommend exploring articles from trusted scientific journals such as Nature Nature and ScienceDirect ScienceDirect. These platforms offer a wealth of knowledge and insights into the latest developments in material science and engineering.

By delving deeper into this exciting field, we can continue to build upon the foundations laid by strain layer transparency, unlocking new possibilities and paving the way for a future where innovation knows no bounds. Together, let’s embrace this journey and discover the extraordinary potential that lies within the layers of our world. 🌍✨

Toni Santos is a visual explorer and microscopic storyteller who delves into the hidden aesthetics of microbial life. Through a fusion of scientific curiosity and artistic insight, Toni transforms the overlooked world of bacteria, fungi, and cellular forms into mesmerizing visual narratives—revealing the elegance, symmetry, and chaos that thrive at microscopic scales.

Rooted in a fascination with life forms too small to see yet too intricate to ignore, Toni’s work captures the bizarre beauty of microbial colonies, biofilms, and spore patterns. These images aren’t just representations—they are celebrations of the artistic intelligence encoded in nature’s tiniest architects.

With a background in visual design and bio-inspiration, Toni merges scientific imaging techniques with creative expression, transforming petri dish cultures, fluorescence microscopy, and microbial textures into works that provoke both wonder and contemplation.

As the creative force behind Vizovex, Toni offers curated visual studies, microbial-inspired designs, and essays that bridge art and microbiology—inviting viewers to reimagine what beauty means at the edge of perception.

His work is a tribute to:

The hidden geometries of living systems

The surprising elegance of microbial growth

The role of micro-life in shaping visual culture

Whether you’re a scientist, artist, or simply curious about the unseen world that sustains us, Toni opens a window into a universe where life writes poetry in colonies and patterns, one microbe, one frame, one breathtaking detail at a time.