In today’s fast-paced and ever-evolving world, the pursuit of perfection is a relentless endeavor that permeates nearly every facet of our lives. Whether it’s crafting the ideal meal, designing a cutting-edge piece of technology, or constructing the perfect building, the quest for excellence never ceases. One area where this relentless pursuit is particularly evident is in the realm of manufacturing and production. Here, the smallest details can make all the difference, and one often-overlooked factor is moisture control. Enter the revolutionary world of moisture-controlled technology—a game-changer that promises to transform the way we approach production processes, leading us to the pinnacle of precision and quality.

Moisture, that ubiquitous element present in the very air we breathe, plays a crucial role in a myriad of industrial and manufacturing processes. Its impact is far-reaching, influencing everything from the texture and shelf-life of food products to the structural integrity of building materials. Yet, despite its significance, moisture is frequently underestimated or misunderstood. This oversight can lead to a host of challenges, including compromised product quality, increased waste, and higher production costs. However, as technology continues to advance, innovative solutions are emerging to tackle these issues head-on. Moisture-controlled technology stands at the forefront of this revolution, offering unprecedented control and precision.

Imagine a world where moisture levels are no longer a variable to be cautiously managed, but a parameter that can be precisely controlled and optimized. This is the promise of moisture-controlled technology. By harnessing the power of sensors, data analytics, and automated systems, manufacturers can now achieve a level of precision that was once unimaginable. This technology enables real-time monitoring and adjustments, ensuring that products are produced under optimal conditions, every single time. The implications of this advancement are profound, promising not only enhanced product quality but also significant cost savings and sustainability benefits.

Throughout this article, we will delve deeper into the fascinating realm of moisture-controlled technology. We will explore its origins, tracing its evolution from rudimentary moisture management techniques to the sophisticated systems in place today. We’ll examine the science behind moisture control, unraveling the complexities of how moisture interacts with various materials and how it can be precisely managed. Furthermore, we’ll highlight some of the most compelling case studies and success stories from industries that have embraced this technology, showcasing the transformative impact it has had on their production processes.

As we journey through the intricacies of mastering moisture, we will also address the future implications of this technology. What does the widespread adoption of moisture-controlled technology mean for industries around the globe? How will it shape the future of manufacturing, and what new possibilities will it unlock? These are just a few of the questions we will explore as we uncover the immense potential of this groundbreaking innovation. So, whether you are a seasoned industry professional, an avid technophile, or simply someone intrigued by the marvels of modern science, join us as we embark on an enlightening exploration of moisture-controlled technology and its role in shaping the future of manufacturing. 💧

The Science of Moisture-Controlled Technology

Moisture-controlled technology represents a significant advancement in the field of material science and engineering. This technology primarily focuses on managing moisture levels within various forms to achieve desired physical and chemical properties. At its core, moisture-controlled technology is about precision—adjusting the moisture content to exact specifications for optimal results. Whether in food production, pharmaceuticals, or construction materials, controlling moisture levels is crucial for product quality, longevity, and performance.

Understanding the science behind this technology requires a deep dive into how moisture interacts with different substances. Moisture affects the texture, weight, and structural integrity of materials. For instance, in food production, maintaining precise moisture levels can enhance flavor, extend shelf life, and prevent spoilage. In pharmaceuticals, it ensures the stability and efficacy of drugs. Meanwhile, in construction, controlling moisture in building materials can prevent issues like mold growth and structural weakness. The role of moisture cannot be overstated, as it is a critical factor in maintaining the integrity and quality of various forms and products.

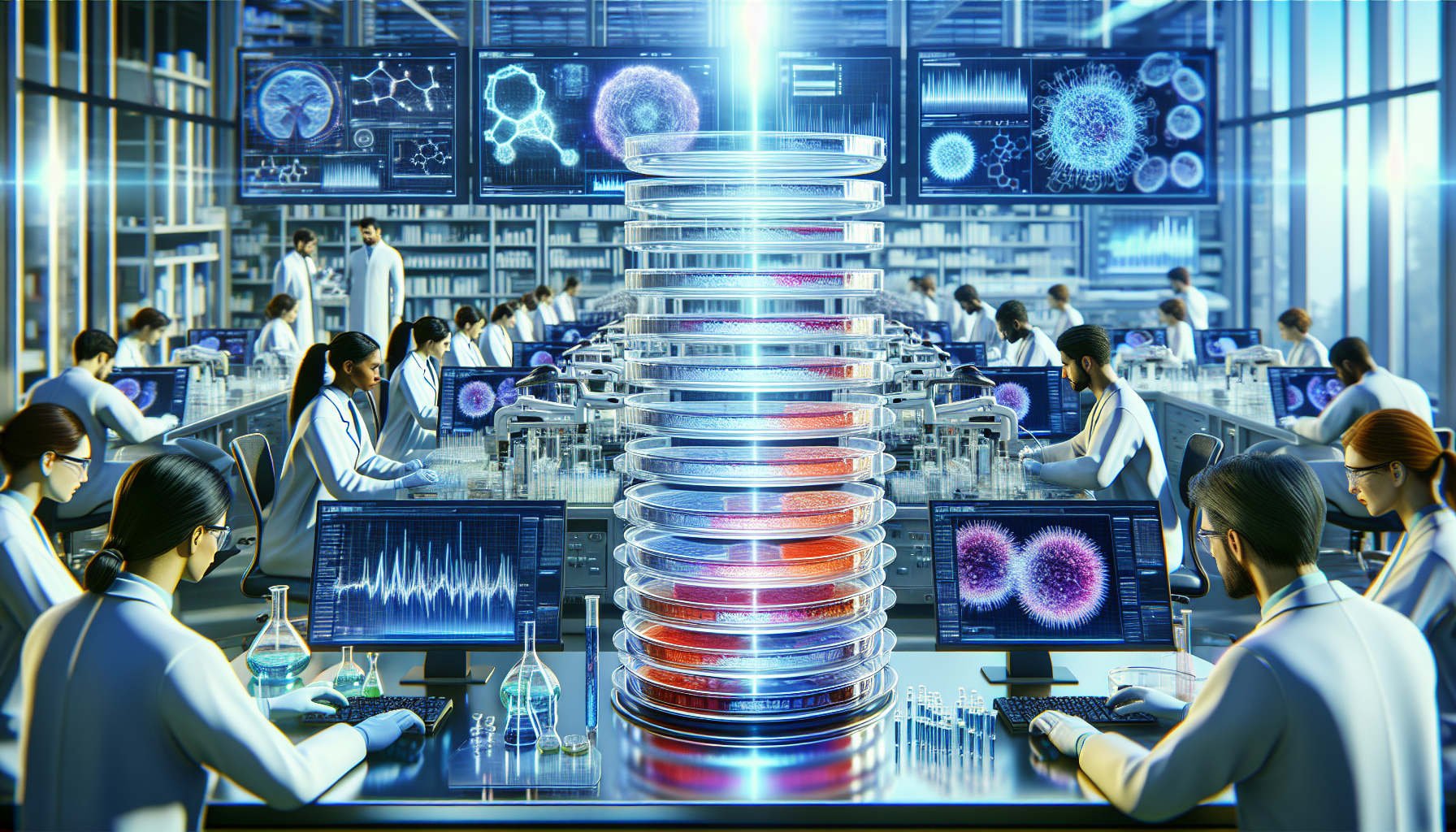

Moreover, moisture-controlled technology employs advanced sensors and algorithms to monitor and regulate humidity levels. These sensors are designed to detect even the smallest changes in moisture content, allowing for real-time adjustments. By doing so, this technology ensures that products maintain their intended quality and performance throughout the production process. This capability is particularly valuable in industries where even slight deviations in moisture content can lead to significant quality issues. The integration of moisture-controlled technology into production processes represents a major step forward in precision manufacturing.

Applications Across Industries

Moisture-controlled technology finds applications across a wide range of industries, each benefiting from its ability to enhance product quality and performance. In the food industry, for example, maintaining precise moisture levels is crucial for ensuring product safety and consistency. This technology allows producers to fine-tune the texture and flavor of their products while extending shelf life. Similarly, in the pharmaceutical industry, moisture control is vital for ensuring drug stability and efficacy, as excessive moisture can lead to degradation or reduced potency.

In the construction industry, moisture control is essential for maintaining the structural integrity of building materials. Excess moisture can lead to issues such as mold growth, structural weakness, and even premature deterioration. By employing moisture-controlled technology, builders can ensure that their materials are free from excess moisture, resulting in safer and more durable structures. The benefits of moisture control extend beyond just quality and performance; they also contribute to sustainability by reducing waste and improving energy efficiency.

The versatility of moisture-controlled technology is evident in its ability to adapt to various industrial needs. Whether it’s adjusting the moisture content in textiles to improve comfort and durability or ensuring the quality of electronic components by preventing moisture-related damage, this technology is revolutionizing industries by offering precision and control. This adaptability is a testament to the transformative impact of moisture-controlled technology on modern manufacturing processes.

Innovations in Moisture-Controlled Technology

Recent innovations in moisture-controlled technology have further expanded its capabilities, making it more efficient and accessible than ever before. One of the key advancements is the development of smart sensors that provide real-time data on moisture levels. These sensors are equipped with advanced algorithms that can predict changes in moisture content and adjust settings automatically to maintain optimal conditions. This level of automation reduces the need for manual intervention, streamlining the production process and improving overall efficiency.

Another significant innovation is the integration of moisture-controlled technology with the Internet of Things (IoT). By connecting moisture sensors to a network, manufacturers can monitor and control moisture levels remotely. This connectivity allows for greater flexibility and responsiveness, enabling manufacturers to make data-driven decisions that optimize their production processes. The IoT integration also facilitates predictive maintenance, allowing for early detection of potential issues before they become significant problems.

In addition to sensor and IoT advancements, researchers are exploring new materials and coatings that enhance moisture control capabilities. These materials are designed to repel or absorb moisture as needed, providing an additional layer of protection and control. By combining these advanced materials with existing moisture-controlled technology, manufacturers can achieve unprecedented levels of precision and performance. The continued innovation in this field promises to unlock new possibilities and applications for moisture-controlled technology across industries.

Future Prospects and Challenges

The future of moisture-controlled technology is bright, with numerous opportunities for growth and development. As industries continue to prioritize quality and efficiency, the demand for advanced moisture control solutions will only increase. Researchers are already exploring new applications and methods to enhance the capabilities of this technology, including the use of artificial intelligence to predict and manage moisture levels more accurately.

However, the widespread adoption of moisture-controlled technology also presents challenges that must be addressed. One of the primary challenges is the cost of implementation, as the initial investment in sensors and equipment can be significant. Manufacturers must carefully weigh the benefits against the costs to determine the feasibility of integrating this technology into their operations. Additionally, there are technical challenges related to sensor accuracy and reliability, as even minor errors can have significant consequences.

Despite these challenges, the potential benefits of moisture-controlled technology far outweigh the drawbacks. By improving product quality, reducing waste, and enhancing efficiency, this technology offers a compelling value proposition for manufacturers across industries. As research and development efforts continue, we can expect to see even more innovative solutions that push the boundaries of what is possible with moisture control.

Practical Implementation and Case Studies

The practical implementation of moisture-controlled technology can be illustrated through various case studies that demonstrate its impact across different sectors. One notable example is the food industry, where moisture control is critical for product quality and safety. Companies have successfully implemented moisture-controlled technology to improve the consistency and shelf life of their products. By using advanced sensors and algorithms, they can maintain precise moisture levels throughout the production process, ensuring that each product meets quality standards.

In the pharmaceutical industry, moisture-controlled technology has been instrumental in improving drug formulation and stability. By controlling moisture levels, pharmaceutical companies can prevent degradation and ensure that medications maintain their intended potency. This technology has also enabled more efficient production processes, reducing waste and increasing yield. As a result, patients receive higher-quality medications that are more effective and reliable.

The construction industry has also benefited from moisture-controlled technology, particularly in the area of building materials. By employing this technology, builders can ensure that materials are free from excess moisture, preventing issues such as mold growth and structural weakness. This has led to safer and more durable structures, enhancing the overall quality of construction projects. The use of moisture-controlled technology in construction demonstrates its versatility and effectiveness in addressing moisture-related challenges.

Best Practices for Implementation

Implementing moisture-controlled technology requires careful planning and execution to achieve the desired results. Here are some best practices to consider when integrating this technology into your operations:

- Conduct a thorough analysis of your current moisture control processes to identify areas for improvement.

- Invest in high-quality sensors and equipment that provide accurate and reliable data.

- Train staff on the use of moisture-controlled technology and emphasize the importance of maintaining optimal moisture levels.

- Continuously monitor and evaluate the performance of your moisture control system to identify areas for further optimization.

- Collaborate with experts and industry partners to stay informed about the latest advancements and best practices in moisture-controlled technology.

By following these best practices, manufacturers can successfully integrate moisture-controlled technology into their operations, improving product quality and efficiency while reducing waste and costs.

For a deeper understanding of moisture-controlled technology, check out this video: Moisture Control: The Key to Perfect Forms – Moisture Technology Channel

Comparison of Moisture-Controlled Technologies

To better understand the various options available in moisture-controlled technology, it’s essential to compare different systems and their capabilities. The table below highlights some of the key differences between various moisture control technologies currently available on the market:

| Technology | Precision | Cost | Applications |

|---|---|---|---|

| Smart Sensors | High | Moderate | Food, Pharmaceuticals, Construction |

| IoT Integration | Very High | High | Industrial, Agriculture, Textiles |

| Advanced Materials | Moderate | Variable | Construction, Electronics, Packaging |

As shown in the table, each technology offers unique benefits and is suited to different applications. Smart sensors provide high precision at a moderate cost, making them ideal for industries where accuracy is paramount. IoT integration offers the highest level of precision and flexibility, although it comes with a higher cost. Advanced materials offer moderate precision and variable costs, but they provide additional protection and control for specific applications.

By carefully evaluating the different options and their respective benefits, manufacturers can choose the most suitable moisture-controlled technology for their specific needs. This decision will ultimately impact the quality, efficiency, and success of their operations, making it a critical consideration for any organization seeking to leverage moisture-controlled technology.

Conclusion

Certainly! Here’s a comprehensive conclusion tailored for the article titled “Mastering Moisture: The Key to Perfect Forms with Moisture-Controlled Technology”:

—

In conclusion, the exploration of moisture-controlled technology reveals its transformative potential across various industries, particularly in achieving optimal product forms and enhancing overall quality. The primary insights from our discussion highlight the critical role that moisture plays in both natural and manufactured settings. By mastering the delicate balance of moisture content, companies can ensure that their products not only meet but exceed consumer expectations in terms of durability, texture, and longevity.

One of the key takeaways from our analysis is the versatility of moisture-controlled technology. Whether in agriculture, where precise water levels can drastically improve crop yield and quality, or in the textile industry, where maintaining specific humidity levels is essential for fabric integrity, the applications are vast and varied. This adaptability underscores the importance of continued innovation and investment in moisture management systems.

Furthermore, the integration of moisture control into manufacturing processes can lead to significant economic and environmental benefits. By optimizing moisture levels, companies can reduce waste, lower energy consumption, and create more sustainable production cycles. This aligns with the growing consumer demand for environmentally friendly products and practices, reinforcing the relevance of moisture control in today’s market.

The technological advancements in moisture control also demonstrate a promising intersection with digitalization. The use of sensors, IoT devices, and data analytics allows for real-time monitoring and adjustments, providing unprecedented precision and control. This not only enhances product quality but also opens up new avenues for research and development, fostering a culture of continuous improvement and innovation.

As we reflect on these points, it becomes clear that mastering moisture is more than just a technical challenge; it is a strategic imperative that can drive competitive advantage. Businesses that prioritize moisture-controlled technology are likely to lead in their respective fields, setting new standards for quality and efficiency.

We encourage you to engage with the concepts discussed in this article by sharing your thoughts and experiences. How has moisture control impacted your industry or personal endeavors? What innovations have you witnessed or implemented in this space? By sharing your insights, you contribute to a broader conversation on the future of moisture management and its potential to reshape industries.

Feel inspired to take action! Whether it’s through implementing new moisture control systems in your operations or advocating for more sustainable practices in your community, every effort counts towards harnessing the full potential of this technology.

Finally, we invite you to delve deeper into the subject with further research. For those interested in exploring the latest advancements and case studies, consider visiting reputable sources such as ScienceDirect and ResearchGate, where you can find peer-reviewed articles and ongoing discussions about moisture-controlled technology.

In embracing the art and science of moisture control, we step into a future of endless possibilities, where perfect forms are not just an aspiration but a reality. 🌱✨

—

Toni Santos is a visual explorer and microscopic storyteller who delves into the hidden aesthetics of microbial life. Through a fusion of scientific curiosity and artistic insight, Toni transforms the overlooked world of bacteria, fungi, and cellular forms into mesmerizing visual narratives—revealing the elegance, symmetry, and chaos that thrive at microscopic scales.

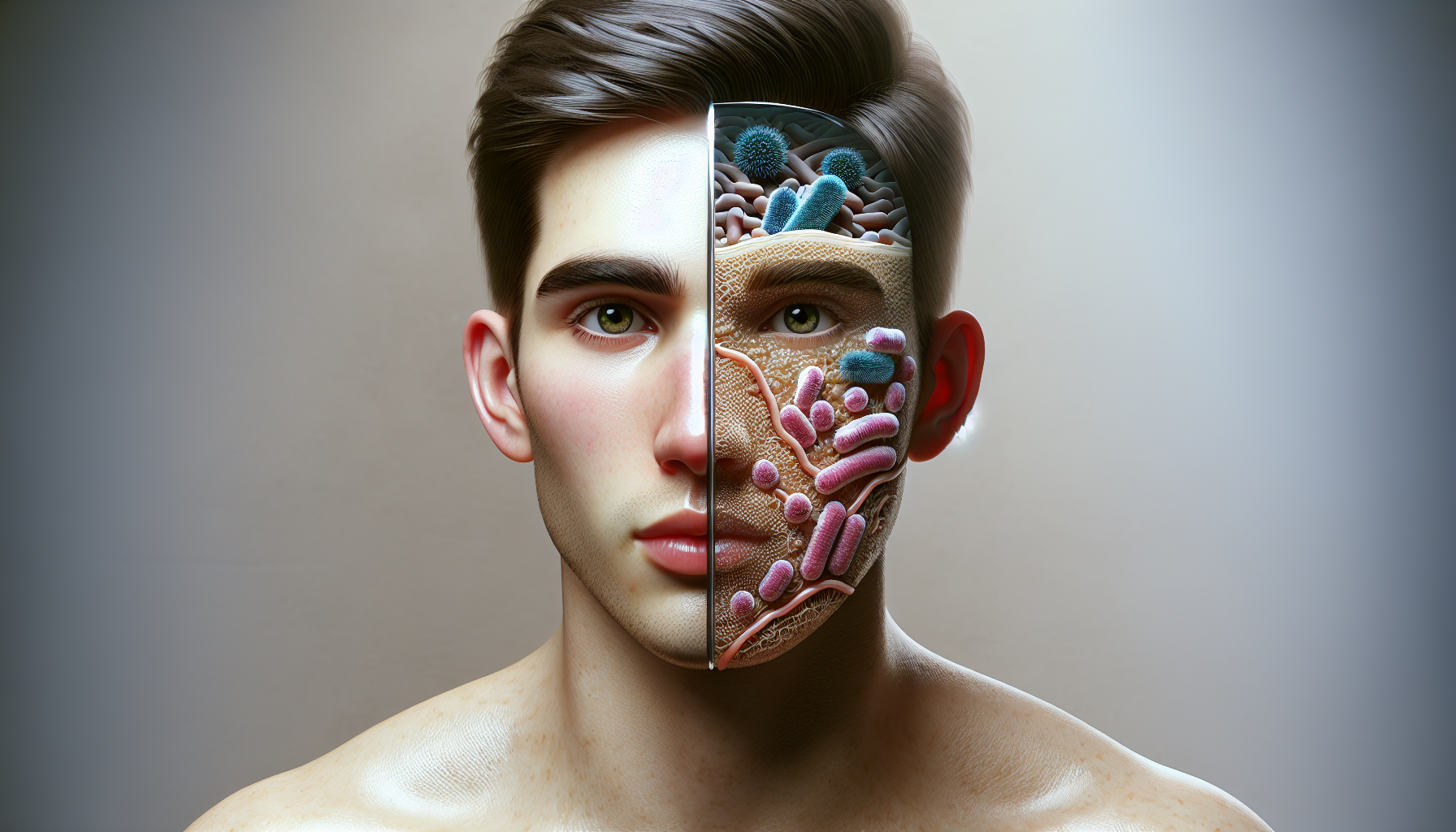

Rooted in a fascination with life forms too small to see yet too intricate to ignore, Toni’s work captures the bizarre beauty of microbial colonies, biofilms, and spore patterns. These images aren’t just representations—they are celebrations of the artistic intelligence encoded in nature’s tiniest architects.

With a background in visual design and bio-inspiration, Toni merges scientific imaging techniques with creative expression, transforming petri dish cultures, fluorescence microscopy, and microbial textures into works that provoke both wonder and contemplation.

As the creative force behind Vizovex, Toni offers curated visual studies, microbial-inspired designs, and essays that bridge art and microbiology—inviting viewers to reimagine what beauty means at the edge of perception.

His work is a tribute to:

The hidden geometries of living systems

The surprising elegance of microbial growth

The role of micro-life in shaping visual culture

Whether you’re a scientist, artist, or simply curious about the unseen world that sustains us, Toni opens a window into a universe where life writes poetry in colonies and patterns, one microbe, one frame, one breathtaking detail at a time.